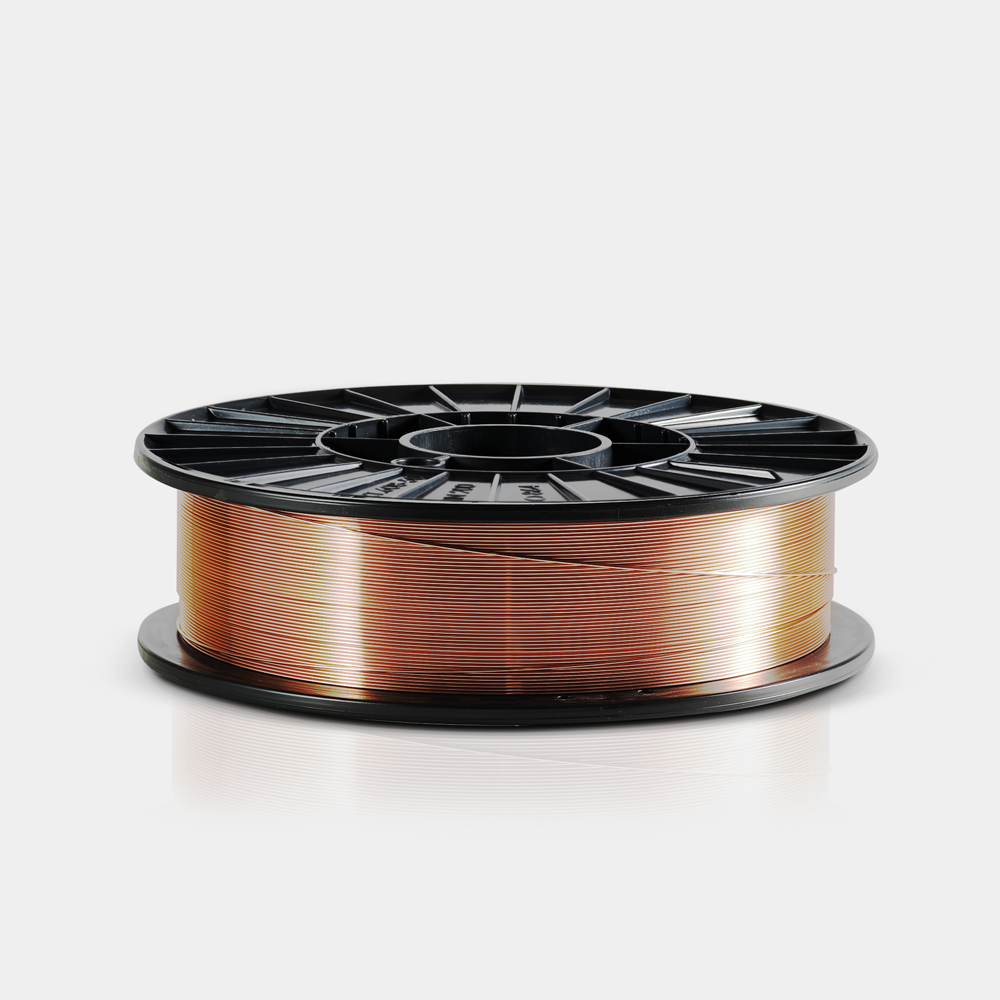

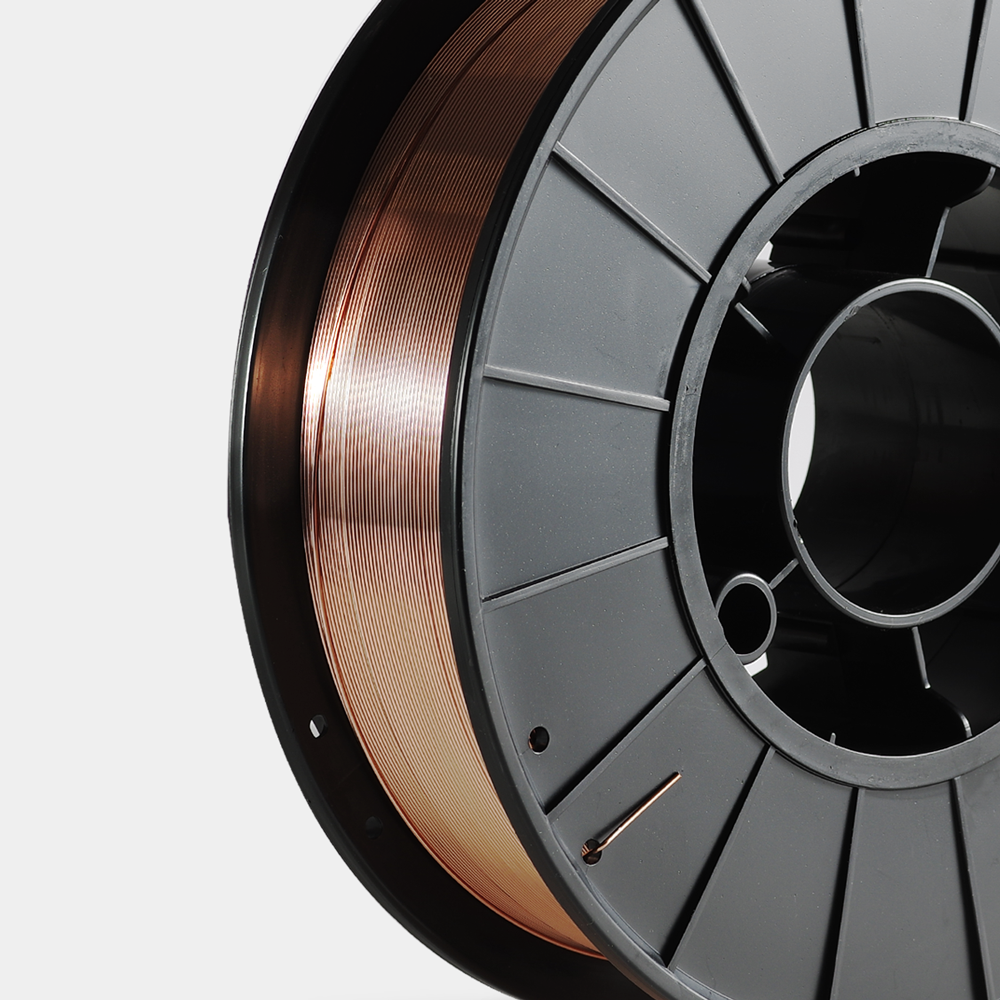

Item Code: WAATU413003

Category

Aluminum

Description

selection not available, try a different combination

selection not available, try a different combination

selection not available, try a different combination

selection not available, try a different combination

Compare